Fact Sheet FS1358

This worksheet focuses on the entire process of growing produce from production through distribution, including direct-to-consumer markets. Specific Food Safety Modernization Act Produce Safety Rule and United States Department of Agriculture third-party audit requirements can be found on our Rutgers On-Farm Food Safety Website.

A well-planned worker training program is key to reducing human pathogen risks in the farm environment. This worksheet will prompt you to identify where workers are coming in direct contact with produce, the type of training your workers should have, and relevant training resources. Worker training should take place upon hire, and programs should be evaluated annually to ensure they continue to meet the farm’s needs as your staffing, equipment, and infrastructure change.

- Draw a rough map of your farm operation. Include all areas where produce is grown, harvested, packed, stored, or sold on the farm. Identify the areas as "production," "harvest," "postharvest," or "distribution." You can consult Section 2 for guidance.

- Review your map. What area of the farm do you have workers involved with the production, harvest, or distribution of produce? (Circle all that apply)

| Activity | Areas this may include |

|---|---|

| Production | Field, greenhouse, tunnel, indoor growing facility, restrooms/portable toilets, employee break areas, compost area, production equipment, water distribution system, water treatment system, water source, storage areas |

| Harvest | Field, greenhouse, tunnel, indoor growing facility, headhouse, storage areas, harvest equipment, restrooms/portable toilets, employee break area, water distribution system |

| Postharvest | Packing and grading areas, storage areas, restrooms, employee break areas, cold rooms, postharvest water systems |

| Distribution | Cold room, headhouse, vehicles, market areas, restrooms |

- What training subject matter is required based on the areas of activity that you indicated? Some training topics may be relevant for multiple activities across the farm. Consider who works in these spaces and how the training may need to be tailored to include risks present in one area and not another.

(Circle all that apply)

| Production | Harvest | Postharvest | Distribution |

|---|---|---|---|

| Worker health and hygiene | Worker health and hygiene | Worker health and hygiene | Worker health and hygiene |

| Maintaining break areas/restrooms and portable toilets / handwashing facilities | Maintaining break areas/restrooms and portable toilets/ handwashing facilities | Maintaining break areas/restrooms and portable toilets / handwashing facilities | Maintaining break areas/restrooms and portable toilets/ handwashing facilities |

| Wildlife intrusion | Water system inspection | Pest control | Produce transportation to markets |

| Soil amendment use | Irrigation water use | Food contact surface cleaning and sanitation | Direct sales of produce to customers |

| Fecal matter identification and response | Wildlife intrusion | Water treatments | Farm visitors |

| Water system inspection | Damaged and/or contaminated produce | General cleaning | |

| Pest control | Waste management | ||

| Harvest tool sanitation | Sorting produce | ||

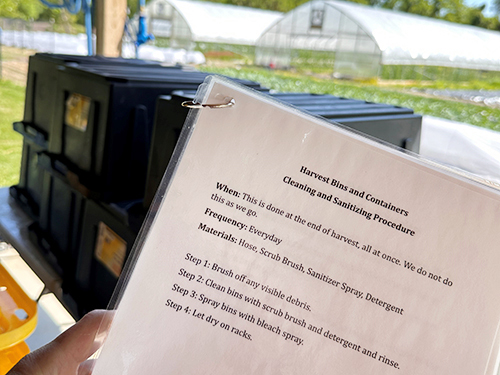

| Harvest container use and sanitation | Packing produce | ||

| Grey water management |

- Identify training resources in Section 5 that may meet the training needs identified in Section 3. Visit our website to access additional resources.

| Training needed | Resource |

| Production –worker health and hygiene | Cornell WHH field training video, YouTube |

- Use these QR codes to access worker training video resources that can be used as part of your worker training program. All your training needs may not be met by videos available online. Make sure you consider the primary language of your workers and the training you are providing. Additional print resources are available on our website that can assist you in tailoring information for your farm’s training needs.

| Topic | Title and Institution | Online access |

|---|---|---|

| Worker Health and Hygiene | Food Safety Video for Field Workers, Cornell University Available in: English, Spanish, Creole, Hmong |

go.rutgers.edu/lasm2bvw

|

| Wildlife assessment | Interactive Wildlife Scouting Simulator, Michigan State University Available in: English |

go.rutgers.edu/tnv76nmo

|

| Compost | Safe Use of Animal Based Soil Amendments, Michigan State University Available in: English |

go.rutgers.edu/l4awa7gz

|

| Cleaning and sanitizing | Cleaning VS Sanitizing, University of Massachusetts Available in: English |

go.rutgers.edu/yoqcmuza

|

| Cleaning and sanitizing | Cleaning and Sanitizing Farm Tools and Equipment, New Mexico State University Available in: English, Spanish |

go.rutgers.edu/tz0g1grc

|

| Single-pass wash line deep cleaning | Single-Pass Wash Line Deep Cleaning How-To, Rutgers Available in: English |

go.rutgers.edu/8hl4u4ya

|

| Water system inspection | Water System Inspection, Michigan State University Available in: English *This video states that a water system inspection is not required for the FSMA PSR. The FDA released the final ag water rule in May of 2024. More information on the requirements, which can include a water system inspection can be found on the FDA website. |

go.rutgers.edu/zl74l38i

|

| Pest management | Best Practices for Pest Management, Iowa State University Available in: English |

go.rutgers.edu/ov5pquje

|

| NECAFS Produce Safety Clearinghouse | Online searchable database of free produce safety resources Available in: Varies |

go.rutgers.edu/uc616u8j

|

This project is funded by: USDA

Award Number: 2022-70020-37591

Photo credit: Photo row across top, left: Meredith Melendez; middle: Michael Monzon; right: Jennifer Matthews

July 2024

Copyright © 2025 Rutgers, The State University of New Jersey. All rights reserved.

For more information: njaes.rutgers.edu.

Cooperating Agencies: Rutgers, The State University of New Jersey, U.S. Department of Agriculture, and Boards of County Commissioners. Rutgers Cooperative Extension, a unit of the Rutgers New Jersey Agricultural Experiment Station, is an equal opportunity program provider and employer.