Bulletin E363

The economic sustainability of an orchard requires maintaining the annual production of fruit at an optimal level. Frost events, specifically during the early spring flower bud development, can cause crop loss which could vary from minor loss of quality and quantity to a total crop loss. Recently, frost events seem to be occurring more frequently. These events have been driven by warmer spring temperatures pushing bud growth earlier, making blossoms more vulnerable to frost damage (NOAA Technical Report, 2012). While sufficient information on frost protection (FP) methods is available, new challenges such as insufficient labor, increased labor costs, environmental regulations, high-density orchards, and newer technologies strongly support revisiting this topic.

There are two types of FP methods; (1) Active, which is employed at the time of frost events and work to either prevent or reduce the loss of thermal energy from plant tissues, and (2) Passive, which are generally cultural practices such as site and cultivar selection, orchard floor management, and manipulation of orchard nutrition which are performed substantially before frost events. This bulletin focuses on Active FP methods. The success of FP will depend on an understanding of the working principles of each method and the combination of environmental factors necessitating its use. This bulletin also incorporates the experiences of local growers who have mastered the use of these methods.

What to Monitor Before Active FP

Active FP methods are costly, and only highly effective when used properly. Frost damage occurs when plant tissues are exposed to subfreezing temperatures (Figure 1). However, it is the co-occurrence of other factors that determines the extent of the damage. All these factors should be monitored and will assist in determining which method to employ and its duration.

Figure 1. Left: Frost damage in apple following the freeze event in 2010 in Pennsylvania (Left Photo by R. Crassweller). Right: Frost damage in peach bloom following the freeze in 2016 in New Jersey (Right Photo by H. Gohil).

Bud Stage

Regular monitoring of the bud development stage, starting from bud swell, will help in determining the actual threat of frost damage. Critical temperatures have been researched and calculated for each bud development stage. For example, in an apple orchard, at 24°F, one can expect up to 90% crop loss at the ‘first pink’ stage, but only marginal to zero percent loss at the green tip stage at the same temperature. An example of the critical temperature for some of the most important pome and stone fruit crops is available from Michigan State University Extension.

However, the critical temperature for damage at a particular bud stage may vary by 4 or 5°F depending on temperatures during the previous few days before the cold event. Therefore, growers should use caution when attempting to use these published critical temperatures for active frost protection methods.

Type of Frost Event

Figure 2. Strong inversion layer over the field in Pennsylvania (Photo by R. Crassweller).

There are two types of frost: advective and radiative frost. Advective frost occurs when a large mass of cold air moves in from another region and replaces warmer air such as during a polar vortex. During such events, there is a rapid movement of cold air to replace warmer air, coupled with high winds, low humidity, and generally the absence of an inversion layer, often creating the potential for a prolonged event. Active FP will generally be ineffective during an advective frost. Conversely, radiative or radiational frost occurs when there is a rapid loss of heat from the ground, usually with a cloudless open sky, dry air, and little wind, which leads to the likely formation of an inversion layer. This frost is more manageable with FP methods.

Inversion Layer

An inversion occurs when a layer of the atmosphere higher in altitude is warmer than the atmosphere lower or close to the ground (Figure 2). This is a reversal of normal temperature behavior. A strong inversion layer can be a source of warmer air and may be substantially warmer than air closer to the ground. For this reason, inversions need to be closely monitored.

Air Temperature

Figure 3. Damaged pistil in closed flower (left) and open flower (middle) and undamaged pistil in open flower (right) following a frost event in peach orchard in New Jersey (Photo by H. Gohil).

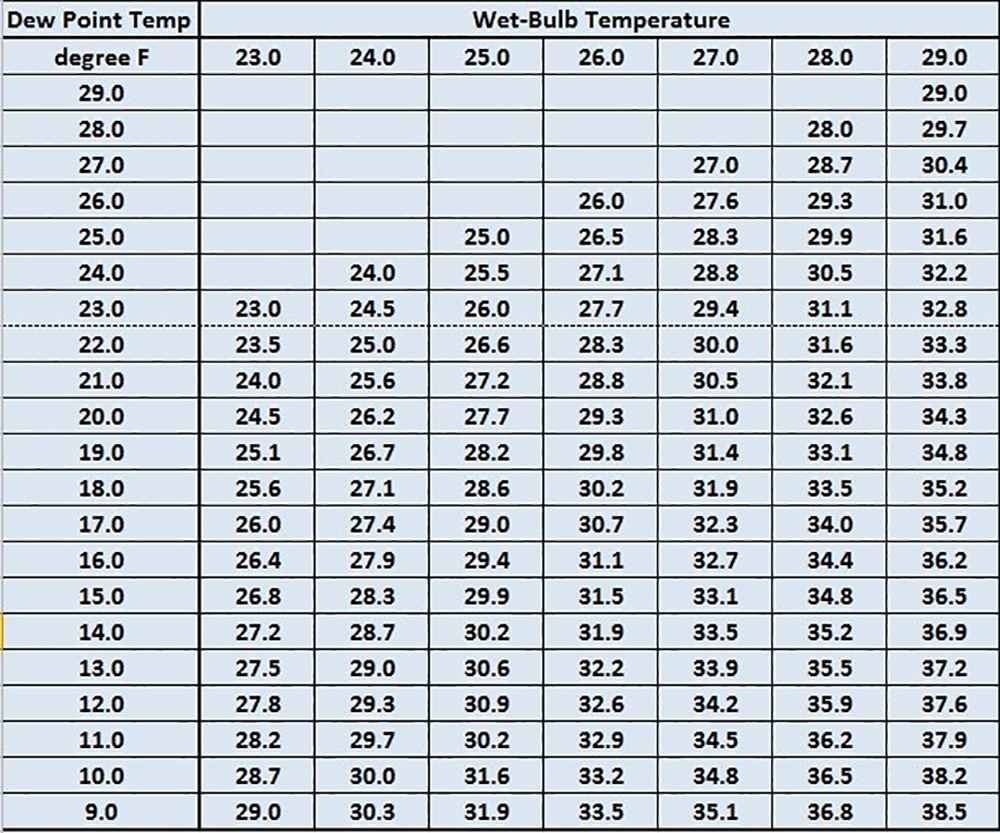

Frost can occur when the ambient temperature dips below freezing (32°F). The hourly rate of falling temperatures and the lowest forecasted temperature should also be monitored. However, the temperature experienced by trees will not necessarily be the same as the reported ambient temperature. To measure the temperature of the flower buds, farmers must take into account the cooling effect of evaporation of the moisture on the trees, which is referred to as the wet-bulb temperature. The wet-bulb temperature is the lowest temperature experienced at the measured relative humidity (RH) of the air. The wet-bulb temperature takes into account the cooling caused by the evaporation of air moisture. Generally, the wet-bulb temperature will be a few degrees lower than the dry-bulb temperature except at the 100% RH. Table 1 provides an example of determining wet bulb temperature, without a wet-bulb thermometer, using the ambient temperature and the dew point. Hand-held and digital psychrometers can be used in the field to determine the wet-bulb temperature. Recently, Knox et al. (2017) at the University of Georgia showed that wet-bulb temperature can be simply derived by ‘subtracting one third the difference between ambient temperature and dew point, from the ambient temperature.’ Modern frost alarms measure wet-bulb temperature, which can directly transmit real-time data to the user’s mobile phone or computer.

Relative Humidity (RH)

The RH is often overlooked in orchard frost management. However, it plays a significant role in determining the extent of frost damage. As RH increases, moisture condenses near sensitive flower parts, which at subfreezing temperatures begins to form ice crystals. According to Levitt (1980), it is likely that freeze injury results from ice forming outside the cell wall and inside the plant tissue (Figure 3). Higher RH can cause greater frost damage compared to low RH, for the same freezing temperature.

Dew point

Dew point is commonly reported as the atmospheric temperature below which water droplets begin to condense, forming dew or fog. At low temperatures, the moisture in the air transitions from a gas to a liquid, as air temperature reaches the dew point. A higher dew point is associated with relatively slow drops in temperature and vice versa. A lower dew point also generally means surface moisture will evaporate quicker.

Cloud Coverage

Clear skies normally result in lower low temperatures than when there is cloud cover trapping radiant energy from the ground.

Wind Speed

Wind is a major determinant of the rate of loss of thermal energy. Almost all of these FP methods will have reduced efficiency at wind speeds above 10 mph, and are therefore not recommended when winds are above 10 mph.

Effective FP requires weather stations and sensors for each of the fields you are seeking to monitor and protect. Data from nearby weather stations may not always be reliable. On-farm weather stations are the most accurate source of weather data and should be linked with a frost alarm. This alarm will sound based on the wet temperature and should be precise down to 0.1°F.

To ensure the sensor is outputting an accurate reading, never install a temperature sensor or weather station next to a building or body of water. Ensure the sensor is no higher off the ground than the lowest flower bud. Sensors should be placed in contact with, or close to buds or leaves of the tree.

If there are significant slopes in your orchard, consider investing in two temperature monitoring devices, monitoring both the lowest and highest points in the orchard. Examples of these instruments and their sources are provided in Table 2. The extension bulletin by Bayer et al. (2017) provides information on the establishment and use of weather stations to monitor all of the above indicators of a frost.

Frost Protection Methods

Active FP methods are mainly of three types, (1) irrigation (2) heat application, and (3) mixing of the air.

Irrigation

Overhead Irrigation

Figure 4. FP using overhead irrigation system in high-density apple orchard in PA (Photo by R. Crassweller).

Overhead Irrigation is one of the most effective of all FP methods, specifically for orchard crops. Water is applied over plant tissues, and at sub-freezing temperatures turns into a layer of ice (Figure 4). This layer prevents the rapid cooling of plant tissue; at the same time, heat is given off as the water freezes during the phase change from liquid to ice, maintaining the temperature at the freezing point. However, to compensate for the loss of thermal energy due to radiation, evaporation, and convection, water has to be continuously applied to continually refreeze which generates additional heat (Figure 5). At wind speeds between 5-10 mph, the effectiveness of overhead irrigation will be reduced, resulting in a need to increase the rate of application. Once all of the ice has melted off of the trees and wires, which is the indication that the temperature is above freezing, the irrigation system can be shut off.

Pros

Overhead irrigation doesn’t produce noise or air pollution as compared to other methods, and it can also be used for summer irrigation. This method will provide FP down to 22°F with no wind, or 24–25°F with a slight wind (Longstroth, 2012). Very few methods can achieve a level of FP to this temperature. This system has low energy consumption when compared to other methods, however, one needs to consider the energy used to pump the water from its source. Operational costs per acre for overhead irrigation are low compared to other methods

Cons

This system requires a substantial amount of water. For example, in an apple orchard setting, about 5,400 gallons of water per acre per hour is required during a frost event (Hannan, 2019). However, research has shown that water applications can be cycled on and off resulting in a reduction of water use by 1/3 (Heinemann, et al., 1992; Heisey, et al., 1994). The development of ice on sprinkler heads must be monitored when temperatures go below 23°F. It may be necessary to use a metal or wooden rod to strike individual nozzles to shatter any ice build-up on younger trees, as the weight of the ice can break scaffolding branches. High installation costs may be incurred specifically if the water source is not adjacent to the block being treated.

Once operating, the system cannot be turned off and must be continuously fed with water. Turning off the system during a frost can cause significantly more damage. It requires a certain degree of skill to maintain the layer of ice, preventing air mixing with water seen as clouded ice, and to avoid applying excessive water by cycling the water on and off to reduce the amount of water applied (Heinemann et al., 1992).

Figure 5. Example of continuous ice formation over apple tree using overhead irrigation. Clear ice and non-cloudy layer indicate successful FP (Photo by R. Crassweller).

Caution

The discharge capacity of the water pump and capacity of the well or pond source should be considered for irrigation and FP well before planting a new orchard. Valves must be installed on all lines to ensure lines can be emptied. Irrigation will cause evaporative cooling; hence wet-bulb temperature should be considered before turning on the system. Overhead sprinklers should not be turned on when the wind speed is more than 10 mph. At temperatures below 23°F, ice can develop over impact heads, and the head can get stuck in one direction, wasting much of the water and minimizing its protective coverage. Regular monitoring is needed to make sure the system is running continuously and effectively. Experience suggests that metal impact heads can freeze just as easily as plastic heads. The main advantage of metal heads is they are less likely to break. However, metal heads are more expensive than plastic heads.

One way to address the challenge of needing a substantial amount of water is to use overhead micro-sprinklers. This method targets mostly the canopy, and as a result, one has better control over the coverage. This system uses about 35–40% less water per acre, and the savings in energy costs are roughly half of overhead irrigation (Rieger, et al., 1990). However, the installation cost could be higher than the overhead impact sprinklers. This system requires a trellis to support half-inch polyethylene laterals. However, since new high-density orchard plantings already use trellising for training young trees, these can also be used to support the installed micro-sprinklers.

Under-tree Sprinkler Systems

Figure 6. FP using under-tree sprinkler irrigation in peach orchard in Delaware (Photo by B. Fifer, Fifer Orchard).

Under-tree sprinkler systems work on the same principle as overhead systems, but with a reduced scope of coverage since it only covers the lower canopy and soil underneath the tree (Figure 6). In addition, it may also be utilized to increase heat transfer from the ground to the air if used according to the same principles as outlined for drip irrigation (see below). If used also for irrigation, it becomes cost-effective. Most systems use small (5/64”–3/32”) low trajectory sprinkler heads operating at 40–50 psi. There are main hoses on each side of the tree, and each micro-sprinkler has a little tube inserted into that hose. Applications range from 0.08–0.12 inch/hr. An application of water at 69.8°F has been used in Mexico and Washington using a large boiler located at the side of the field. This additional cost to heat the water has to be added to the cost-effectiveness equation of this system. This under-tree system may be preferred over another irrigation delivery system when well or pond capacity is limited. It uses much less water compared to the overhead system but with lower effectiveness, particularly for mature trees.

Drip Irrigation

Few orchards in the Mid-Atlantic region use drip irrigation systems since relatively high average precipitation necessitates limited supplemental water during the growing season or prolonged droughts. If soil is irrigated to field capacity (maximum water holding capacity of that soil), it can then store as much heat in the orchard soil as possible during the day and increase the loss of radiative heat during the night. In some soils, it may take more time to “top up” the soil profile. Drip irrigation, in combination with a weed-free strip under a tree, raised the temperature of the orchard floor by 3–5°F (Snyder and de Melo-Abreu, 2005). It may require more than 8–10 hours of irrigation for heavier soils to reach field capacity. Again, this approach should be avoided if the wind speed is forecasted to be more than 10 mph.

Heat Application

During sub-freezing temperature events, additional heat can be supplied to the orchard through burning propane or natural gas. The introduced heat replaces that lost by radiation and wind. However, this can be highly inefficient as the heat created can be lost to the sky, especially if the orchard area is large. Oil burning orchard heaters, also called Smudge pots, are relatively cheaper compared to permanently installed systems. A permanent heating system requires laying underground pipes which must handle certain maximum pressure in case there is a failure at the tank. The heat from the burned fuel keeps the surrounding air warmer by up to 3–5°F, depending on the wind speed. At wind speeds greater than 10 mph, the rate of heat dissipation is greater than heat addition. Considering installation and fuel costs, it is a very expensive system unless you are a retail orchard grower located in a high-value market area.

Mobile Heaters

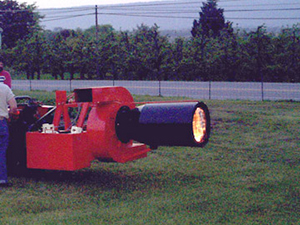

These heaters have propane tanks, a heater, and vents that are pulled through the orchard by a tractor. The moving tractor applies warmer air through the vents to the tree canopy area (Figure 7). After the tractor passes, the warm air may mix with the cooler air, moving away from the tree. Fortunately, there is no need for immediate reheating, as the deposition of ice crystals does not kill the plant tissue if warm air is applied before the ice crystals begin to freeze plant tissues. The machines trade named ‘Frost Buster’ and ‘Frost Dragons’ use propane burners and can effectively protect 5–6 acres at temperatures down to 23°F, or more at higher temperatures.

Figure 7. FP using mobile propane heater (Photo by R. Crassweller).

Using a mobile heater in a traditionally spaced peach orchard, you can drive down every other row, while in a high-density apple orchard it can cover multiple rows. Hot air is dispersed 150–200 feet evenly in both directions. Growers must make a carefully-timed loop to prevent overheating or cooling the orchard. If returning to the same trees too soon or the heater vents are too close to the flower buds, the system may scorch the buds. These machines could cost upwards of $25,000 per unit. Examples of these instruments and their sources are provided in Table 2.

Pros

In a situation where water is scarce, heat application may be the only option for FP. If done correctly, it can be effective down to 23°F. These mobile units may be less expensive than an in-ground permanent heating system, affording the flexibility of moving heat application units within and to different orchard blocks.

Cons

Cost-effectiveness of all heater-based methods depends on the current market price of fuel. Having large propane tanks on the back of the tractor could be dangerous. However, newer designs are much safer, easier to operate, and can be operated for a longer period of time. In hilly terrain that requires slower tractor speeds, using this method would decrease the potential size of the protected area.

Caution

If using this method, one must place thermometers throughout the orchard and carefully note the affected temperature change. There may be pockets within the orchard that require more FP than others. Growers have commented that the most common cause of a mobile heating machine not being effective is because it was started earlier than needed and ran out of propane before dawn, or due to the loss of pressure when all tanks aboard the tractor have less than 50% fuel left (M. Boyer, personal communication). The machine can be unwieldy, and safe operation depends on good driving conditions in the orchard. In any case, depending on the length of the row and the shape of the orchard, the grower should return to the starting spot within 10 minutes, before the applied heat is lost to dissipation.

Mixing Air

A large mass of relatively warmer air may be available when an inversion layer forms above the orchard. That air can be mixed to prevent cold air stratification and to bring the temperature in the tree canopy area above the critical temperature.

Wind Machines

Figure 8. Wind machine in apple block of Gardenhour Orchards in Maryland (Photo by R. Crassweller).

Wind machines are designed to do just that and are becoming more popular (Figure 8). Wind machines can also be used if there is no inversion layer, though they may not be as effective. The machines can be equipped with a controller which can automatically turn them on or off at a designated temperature. Also, connecting the frost alarm to these wind machines can help in reducing excess hours of electricity and noise. Temperature probes should be placed strategically throughout the orchard to reflect the overall ambient temperature in the flower zone area. A single machine can be effective for up to 10 acres, but total coverage will depend on the orchard site and the size of the machine (Ballard and Proebsting, 1972).

Overlapping coverage areas also assures much better coverage—in a 70-acre orchard, one may need 10 machines instead of 7. Natural or predominant wind direction should be considered when designing and placing wind machines in your orchard. Examples of these instruments and suppliers are provided in Table 2.

Pros

Though the installation cost is very high, the operating cost can be quite low. This method requires much less labor and uses significantly less fuel than other methods, and the investment has a relatively long lifespan.

Cons

These machines are very large (27-30 feet tall) and can be quite loud. They are less effective in the absence of a strong inversion layer and work best when trying to maintain a determined temperature rather than heating the orchard. Wind machines can cost up to $40,000 depending on the accessories.

Portable Wind Machines

Portable wind machines have some applications in small, specific locations. In orchards with rolling terrain, the strategic placement of a portable wind machine can alleviate cold air accumulation in low spots. The fan operates from the PTO (Power Take-off) shaft of a tractor, preventing cold air from accumulating. Tow and Blow portable wind machines are one example.

Pros

These portable wind machines are highly effective as a site-specific method for dips or lower elevations within an orchard and are less expensive than a large wind machine.

Cons

They are only useful in a limited site and require a running tractor with an engaged PTO throughout the frost event.

Helicopters

Helicopters can also be used for the same air mixing purpose and work on the same principle as a wind machine (Figure 9). It is advised to use helicopters only if there is an inversion layer. One helicopter can be used to protect up to 30 acres when the temperature is about 28°F, which can raise the orchard temperature by 4°F a minute after its pass (B. Fifer, personal communication). It should pass over the entire area to be protected every 6–7 min to prevent cold air stratification (Snyder, 2002). Strategically placed lights surrounding the orchard at night can help the pilot determine the boundaries of the orchard. Operating costs for this method are very high, as renting a helicopter can cost around $1500/hr. However, considering the area covered (30 acres) and the duration of operation (4 hours), it can cost around $200/acre, which can be very cost-effective when compared to other methods. For the best effectiveness, the ground crew should communicate to the pilot the current observed temperature, both before and after they pass.

Figure 9. FP using helicopter in Fifer Orchard, Delaware (Photo by F. Fifer).

Pros

Helicopters can cover a substantially large area in a relatively short period. While there is no installation expense, rental rates are high, and availability may be limited. This method may be a good option in areas where FP is only occasionally required.

Cons

Service may not be readily available, and pilots may experience dangerous operating conditions due to poor visibility and orchard terrain. Varying degrees of success have been reported with air mixing via helicopters. If there is no inversion layer, this method is ineffective. The service provider may also ask for holding fees which sometimes are nonrefundable.

Chemical Methods

More recently, there have been some spray formulations available for FP in an orchard setting, but more research is needed. For example, plant growth regulators Promalin® and Perlan®, and mixtures of Gibberellins A4A7 plus 6-BA, have been labeled for use on apple, which if applied immediately following a frost event, can help fruit set. Ice-nucleating bacteria, (e.g. trade name BlightBan®) can be applied in a spray to trees prior to a frost, allowing ice crystals to form around them rather than plant parts. Anti-freeze formulations such as FreezePruf are also available (Francko et al., 2011).

In summary, fruit crops are a high-value commodity and to remain economically viable, orchard owners and managers need to adopt FP methods. Improved understanding of FP methods and their application can greatly increase the chances of successful FP. When choosing a method, growers must consider the available resources and limitations of that method and the orchard location and situation. Each method has several limitations, including a low temperature limit for orchard protection and how it is affected by other environmental factors such as prevailing wind and humidity.

References

| Instrument | Trade name | Manufacturer |

|---|---|---|

| Frost Alarm | Frost Alarm | Agro Frost www.oescoinc.com 800-634-5557 |

| Watch Dog Color | Spectrum Technologies specmeters.com 800-248-8873 |

|

| HOBO Rx 3000 | Onset onsetcomp.com 1-800-564-4377 |

|

| Heater | Ag Heat Propane Heater | Ag Heat Inc. agheat.com 541-490-1928 or 541-400-4875 |

| Frost Dragons | Dynamic Dezigns dynamicdezigns.com/frostcontrol.html 800-567-8264 |

|

| Frost Busters | Agro Frost www.oescoinc.com 800-634-5557 |

|

| Wind Machine | Wind Machine | Orchard Rite orchard-rite.com 616-971-8177 |

| Tow and Blow | Vailmont Vineyards vailmontvineyards.com 905-563-2880 |

|

| Weather Stations | AcuRite | AcuRite acurite.com Online chat support: support.acurite.com/hc/en-us |

| Ambient Weather WS Series | Ambient Weather ambientweather.com 480-346-3380 or support@AmbientWeather.com |

|

| Vantage Pro | Davis Instruments davisinstruments.com 510-732-7814 |

|

| Zentra Systems | Meter Environment metergroup.com 509-332-5601 |

|

| AgroMET-MB MK-III | RainWise Inc. rainwise.com 800- 762-5723 |

Mention or display of a trademark, proprietary product, or firm in text or figures does not constitute an endorsement by Rutgers Cooperative Extension and does not imply approval to the exclusion of other suitable products or firms.

July 2020

Copyright © 2024 Rutgers, The State University of New Jersey. All rights reserved.

For more information: njaes.rutgers.edu.

Cooperating Agencies: Rutgers, The State University of New Jersey, U.S. Department of Agriculture, and Boards of County Commissioners. Rutgers Cooperative Extension, a unit of the Rutgers New Jersey Agricultural Experiment Station, is an equal opportunity program provider and employer.