Fact Sheet FS1343

There is considerable interest in the production of commercial hemp in New Jersey. In addition to the use of hemp flowers for CBD, hemp is also used for a wide variety of other consumer and industrial products. The diversity of raw materials that can be produced by this plant makes industrial hemp a viable resource for agriculture, medicine, food, textiles, construction, and other industries. Currently, there is limited production research being conducted in New Jersey and across the northeastern United States to address the feasibility of hemp production. This fact sheet is one in a series of publications covering commercial production practices for hemp for end-use products including fiber, grain, and cannabinoid (CBD) production.

Botanically, hemp and marijuana are the same species of plant, Cannabis sativa. Many different cultivars or varieties of Cannabis have been developed and selected for distinctly different end-uses. Much in the same way that both popcorn and sweet corn are types of corn, their end uses differ. The ultimate end-use of the desired hemp product dictates which plant varieties, types, and production systems are chosen.

Fiber Production

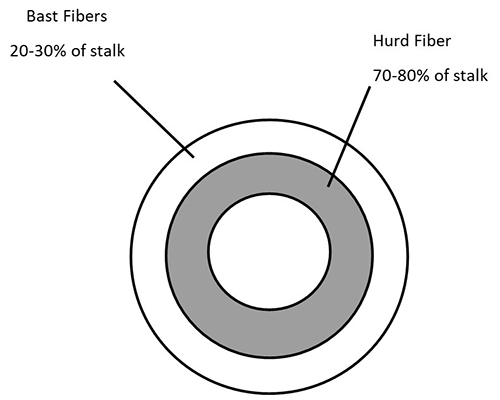

Hemp fiber represents one sector of the hemp market. Hemp is a bast fiber plant like jute. Hemp fiber consists of two types: bast and hurd. Certain varieties of hemp are grown for fiber content. Fiber is harvested from the stalks of hemp fiber varieties and consists of long bast fibers (2–25 mm) and shorter hurd fibers. The bast fibers are a higher-quality fiber found in the outer portion of the stalk. These long fibers are hollow inside and very strong, making them ideal fibers for various products including high quality paper, fabrics and textiles, cordage, insulation, and carpeting. The shorter hurd fibers have a higher lignin content and are woodier than the bast fibers, making them ideal for use in the production of materials such as fiberboard, paper additives, animal bedding, additives in plastics, spill absorbents, and mortar. Hemp fibers are also being used as components in building materials such as hempcrete and as a replacement for synthetic fiber composite in automobile interiors. These new uses make hemp fiber production a potentially environmentally-friendly and less expensive natural alternative to other fibers.

Figure 1. A representative cross section of a hemp fiber stem.

Agronomics of Hemp for Fiber Production

It is important to acknowledge that since the early twentieth century, there have been limited agronomic studies investigating hemp. This fact makes past research-based agronomic recommendations impractical since inputs and growing methods have greatly changed. Limited university research has demonstrated that production recommendations will vary tremendously based on crop end-use genetics. For example, varieties grown for fiber production will have different production systems, fertility regimes, harvest, and storage needs. Rutgers Cooperative Extension is currently conducting research to develop these recommendations.

Soils

Hemp is most successfully grown in loose, well-aerated, and loamy soils. In addition, the soil should have adequate fertility and an abundance of organic matter (> 2%). In New Jersey, most soils are mineral soils and maintaining high organic matter is a challenge, especially with tillage. The first step is to test for soil pH and fertility levels. Hemp performs best in soils with a pH between 6.2 and 7.0.

Variety Selection

Several factors should be considered when selecting a variety. Growers should carefully consider varieties based on the final plant part/parts to be harvested. Varieties developed for specific end-uses may also have varying physical plant attributes which may result in significantly different production practices. Fiber varieties are often taller and planted at higher seeding rates per acre to promote fiber yield. Dual use varieties produce both fiber and seed, but do not have the yields or quality of single purpose cultivars. It is not uncommon for producers to harvest hemp grain with conventional grain combines and subsequently harvest the remaining stems for fiber. This is the most common example of a dual-purpose industrial hemp crop.

Seeding Rate

When growing for fiber only production, the seeding rate is often double what is common for grain production. Recommended seeding rates range from 40 to 60 lbs./A on close row spacing (6"–8" between rows). Research is currently limited regarding seeding rates to achieve high yield and quality fiber specific to New Jersey. Hemp for fiber is planted in dense stands (800,000–1,000,000 plants per acre) to promote taller height and discourage branching and flowering. Higher seeding rates result in high plant population with tall thin plants with longer internodes.

Fertility

Limited replicated research conducted to develop fertilizer recommendations for hemp production for fiber is available. Much of the reported recommendations come from universities where growing conditions may be significantly different compared to New Jersey. In general, recommendations for fiber production are similar to high-yielding wheat or average field corn production.

Nitrogen

Nitrogen (N), considered the most crucial nutrient in hemp production, plays a significant role in crop nutrition and yield. Nitrogen fertilization rates are heavily influenced by the crop end use. Application of N fertilizers positively influences plant height and biomass. Nitrogen rates for fiber production are generally between 100–140 lbs./A broadcast. Timing of nitrogen applications will depend on factors such as cropping system, previous fertilizer applications and soil characteristics.

Phosphorus

Phosphorous (P) is an essential nutrient throughout all hemp growth stages. However, its demand gradually increases as the plant matures. P is also essential during the early growth stages of hemp as it plays a major role in plant strength, root development, and pest resistance. P application has been found to increase plant height in hemp, yet current findings show its effects on hemp biomass and seed yields were inconsistent. Phosphorus rates for fiber production should be based on soil test results. Under optimum soil P conditions, phosphorus rates should be approximately 50 lbs./A.

Potassium

Potassium (K) uptake increases as the crop grows, which is similar to trends observed for P. However, in the case of fiber hemp varieties, the peak uptake occurs during fiber developmental stages. Potassium rates should be based on soil test reports. For optimum conditions, potassium rates should be approximately 60 lbs./A.

Fiber Harvest

The harvest window for fiber has been reported to be when plants are between bloom and early seed set. Hemp fiber crops can be over 8 ft tall and can reach up to 12 ft. in height at maturity. Equipment used for cutting hemp must be able to accommodate this large volume. Standard swathers generally cannot handle hemp fiber crops. Many first-time producers have found that a sickle bar mower may work well for cutting hemp for fiber. The goal is to reduce stalk moisture to less than 15% before baling and should continue to dry to about 10% in the bale. Following cutting, fiber hemp must undergo a process known as retting. During retting, the chemical bonds that hold hurd and bast fibers together are broken, allowing the fibers to be separated. There are two main types of retting: field retting and water retting. Although water retting may produce a higher quality fiber, it is very labor-intensive and costly. As a result, field retting is commonly used. During field retting plants are essentially left in the field long enough for dew and rainfall to result in separation of fibers. With field retting, a considerable time between cutting and baling may be necessary. Experience in Canadian production has shown the length of retting time is normally 21 to 28 days when industrial hemp is cut for fiber during the late summer. Once moisture is under 15 percent, no more retting will take place. Hemp is baled into large round bales or large square bales, depending on processing equipment. If hemp fiber is dried before it’s baled and stored out of the elements, climate-controlled facilities or other special considerations aren’t generally needed.

| Seeding Rate: | 40–60 #/A (pure live seed) 800,000–1,000,000 plants/A |

| Row Spacing: | 6"–8" |

| pH: | 6.2–7.0 |

| Fertility: (Based on optimum soil test levels) |

Nitrogen- 50–60 #/A Phosphorus- 40–60 #/A Potassium- 40–60 #/A |

| Harvest: | Between early bloom and seed set |

Fiber bales shouldn’t be stored outdoors under plastic because moisture can wick up from the ground and spoil the bales. Based on experience with hay handling and storage, it is suggested that hemp fiber should be stored off the ground to prevent moisture absorption. As with hay, hemp fiber is sometimes stored on wooden pallets.

Conclusions

Although there is significant interest in hemp production in the northeastern United States and New Jersey, it is important to keep in mind that there have been very few U.S.-based agronomic research studies on hemp since the early 20th century, particularly regarding production for fiber. Information from previous research is important and useful but may not always be completely applicable for modern production systems. Industrial hemp is an untested crop in New Jersey. As such, research is needed to provide data on planting, management, fertility, harvesting, and processing specific to New Jersey conditions.

While hemp production may provide an opportunity in New Jersey, it is crucial that producers carefully examine the market and accessibility of marketing channels as part of their overall operation. As is the case with any new and emerging agricultural product, limited data exists to quantify the economic feasibility of industrial hemp production in New Jersey.

Additional Resources

- Johnson, R. 2018. Hemp as an Agricultural Commodity, Congressional Research Service (PDF)

- Thompson, E.C., Berger, M.C., Allen, S. 1998. Economic Impact of Industrial Hemp in Kentucky. University of Kentucky, Center for Business and Economic Research, Lexington, KY.

- Walker, E. 2015. Status of Industrial Hemp in Tennessee (PDF). Accessed, 1 May 2021.

- Williams, D.W., Mundel, R. 2018. An Introduction to Industrial Hemp and Hemp Agronomy (PDF). Cooperative Extension Service Publication ID-250. College of Agriculture, Food and Environment, University of Kentucky.

June 2022

Copyright © 2024 Rutgers, The State University of New Jersey. All rights reserved.

For more information: njaes.rutgers.edu.

Cooperating Agencies: Rutgers, The State University of New Jersey, U.S. Department of Agriculture, and Boards of County Commissioners. Rutgers Cooperative Extension, a unit of the Rutgers New Jersey Agricultural Experiment Station, is an equal opportunity program provider and employer.